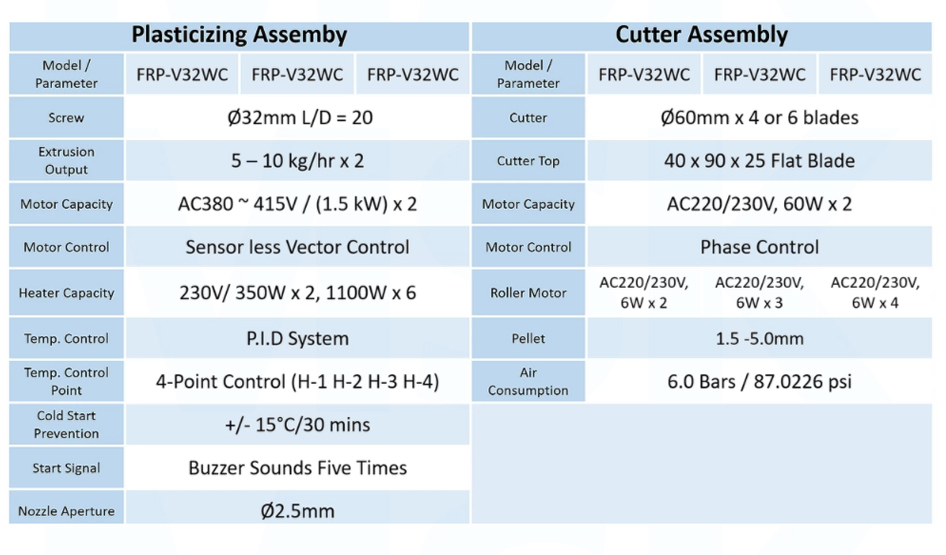

Pelletizer Machine

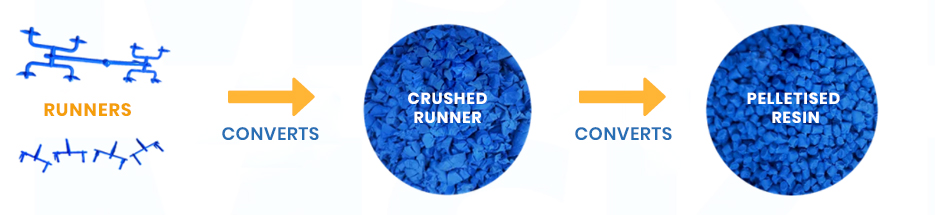

The MSK Eco-efficiency Pelletizer Machine recycles crushed runners, re-pellets the material and returning it to the hopper of the injection molding machine.

Features:

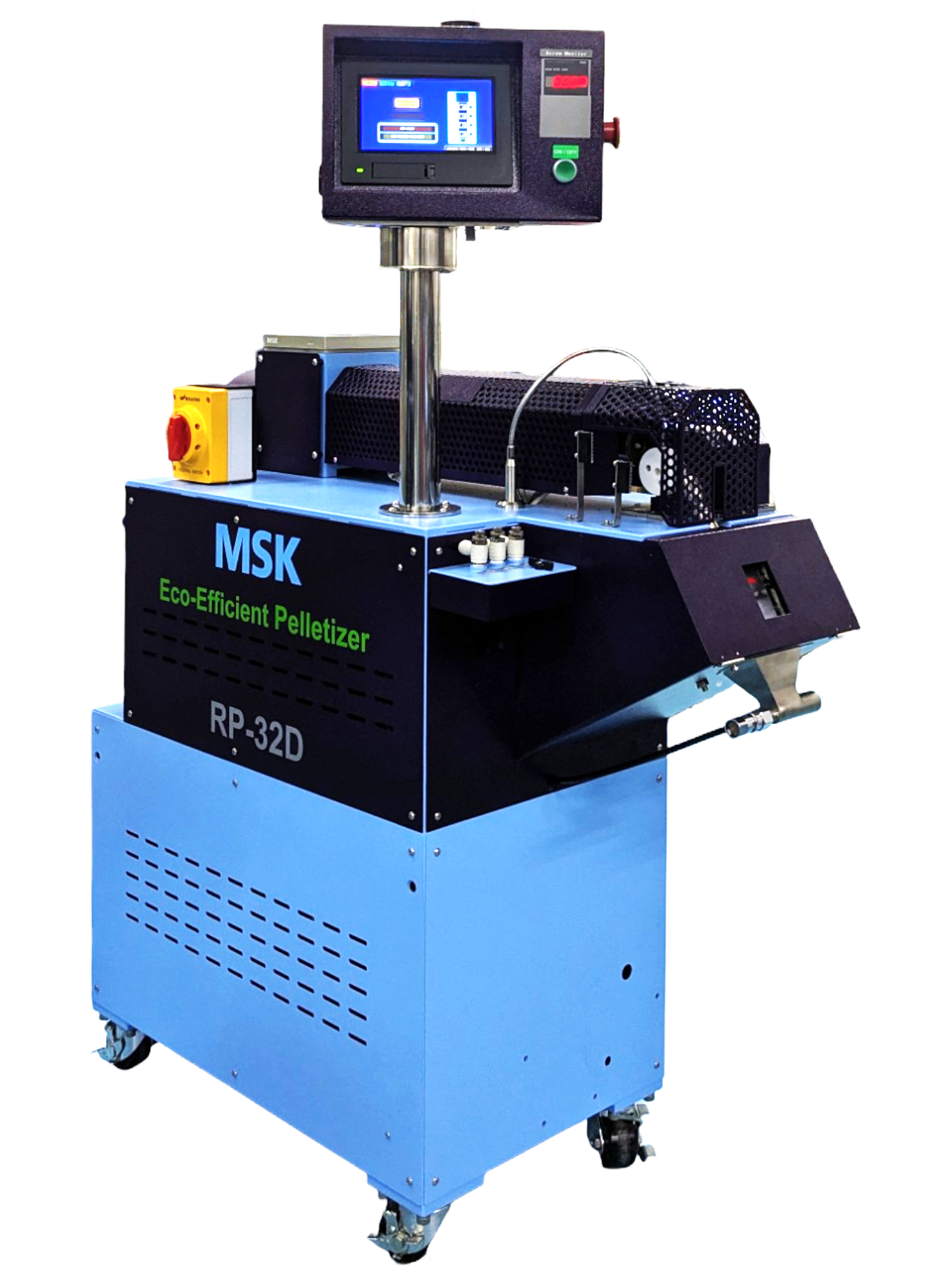

- Touch screen controller allows for easy operations and troubleshooting.

- Output pellet quantity: 5kg to 10kg per barrel. Actual output may differ depending on type or resin and operating conditions, etc.

- Size of the pelletized resins are adjustable according to requirements.

- Developed unit that works well for all types of resins.

- It is a hot cutting machine with no water cooling system required.

- Air cooling system makes material appraisal (Tensile strength, Stretch, Flexural strength, Flexural elasticity, Melt Flow index) of recycled pellets better in comparison to water cooling.

- Equipment cost is easily justified by material savings.

- Process temperature required is 10% lower than the material melting temperature.

- Properties of pelletized resin are the same as the crushed material’s.

How it will reduce your costs:

- Little manpower required to handle the process.

- Able to regrind and pelletize crushed mini runners to the same size as virgin materials.

- As such, the pellets will be evenly mixed and melted to ensure uniformed quality.

- 0% wastage – All waste materials can be recycled, unlike crushed materials.

- Lesser virgin material required as recycled material is able to produce equally good quality products.

- Lower investment with greater returns.

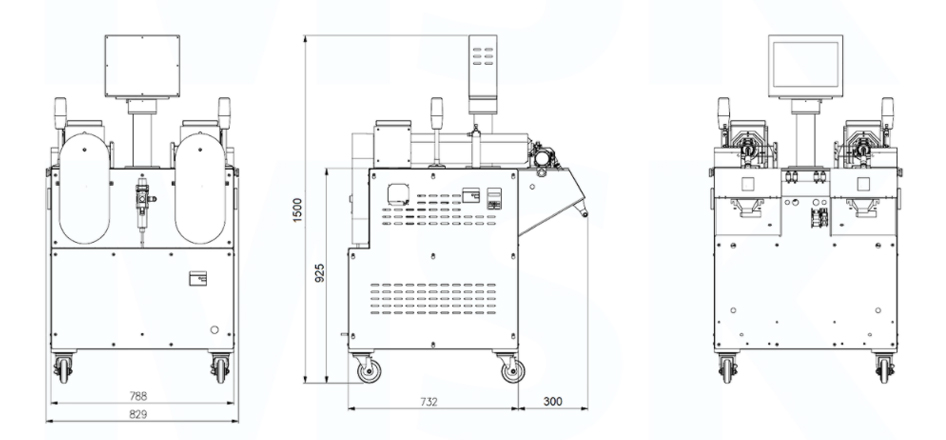

RP-32E

(Extended)

RP-32D

(Direct)

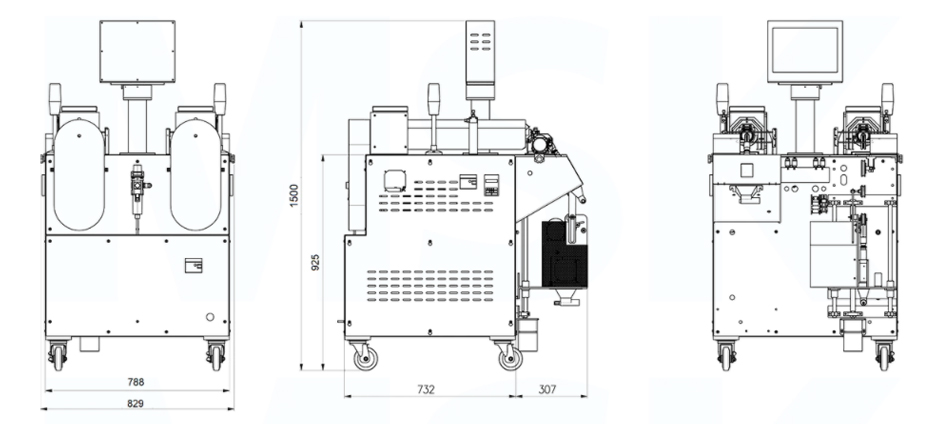

RP-32EE

(Extended)

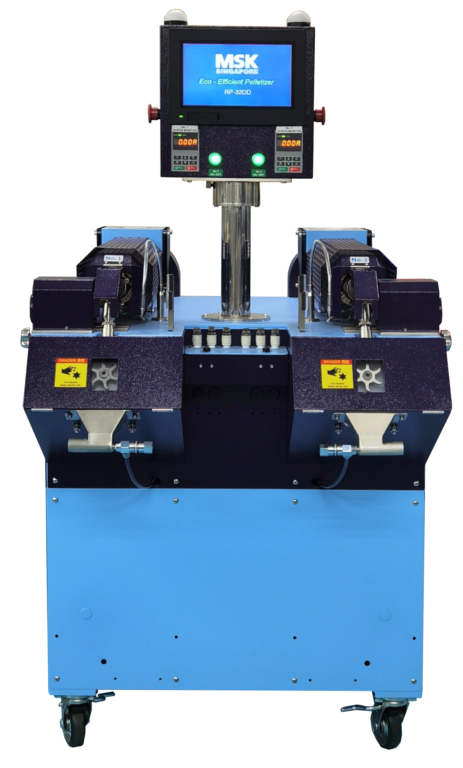

RP-32DD

(Direct)

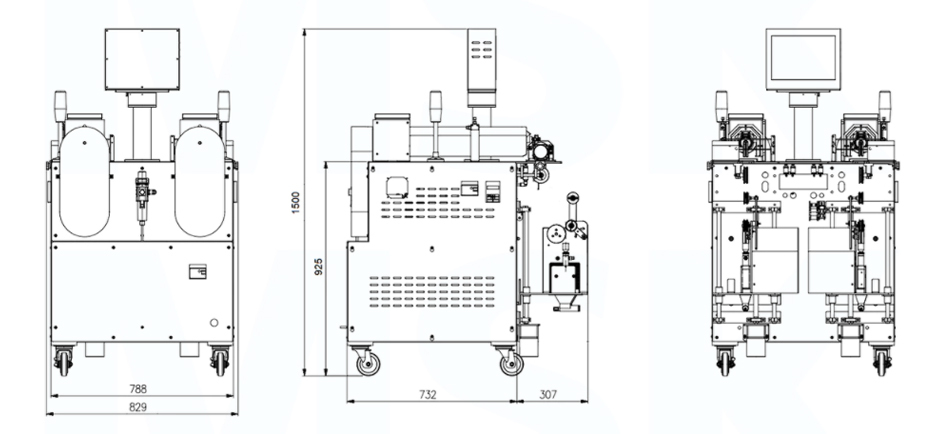

RP-32DE

(Half Extended)