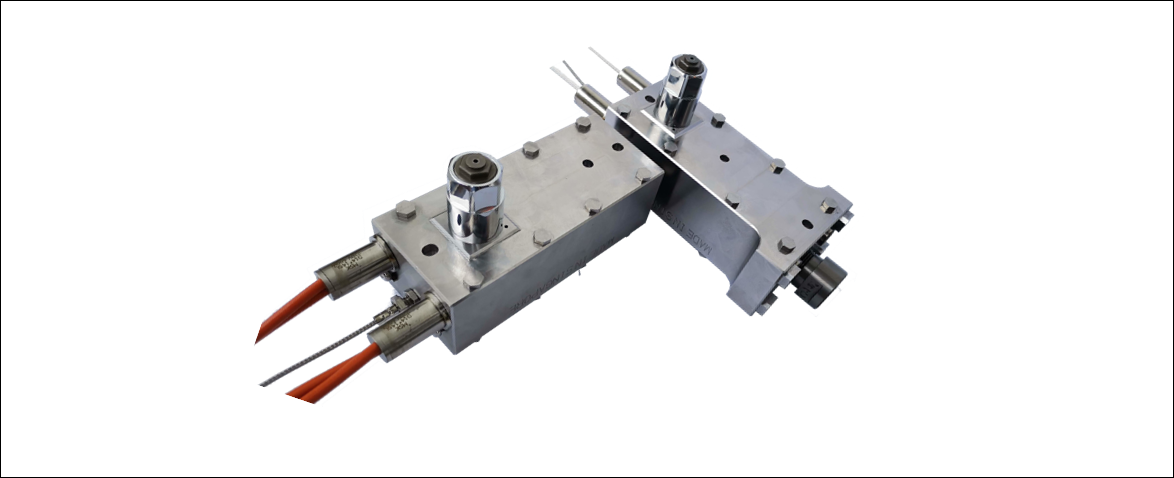

Mini Runner System

The MSK Mini Runner System is specially designed for injection molding machines, fitted with an inner structure differing fundamentally from existing hot runner devices.

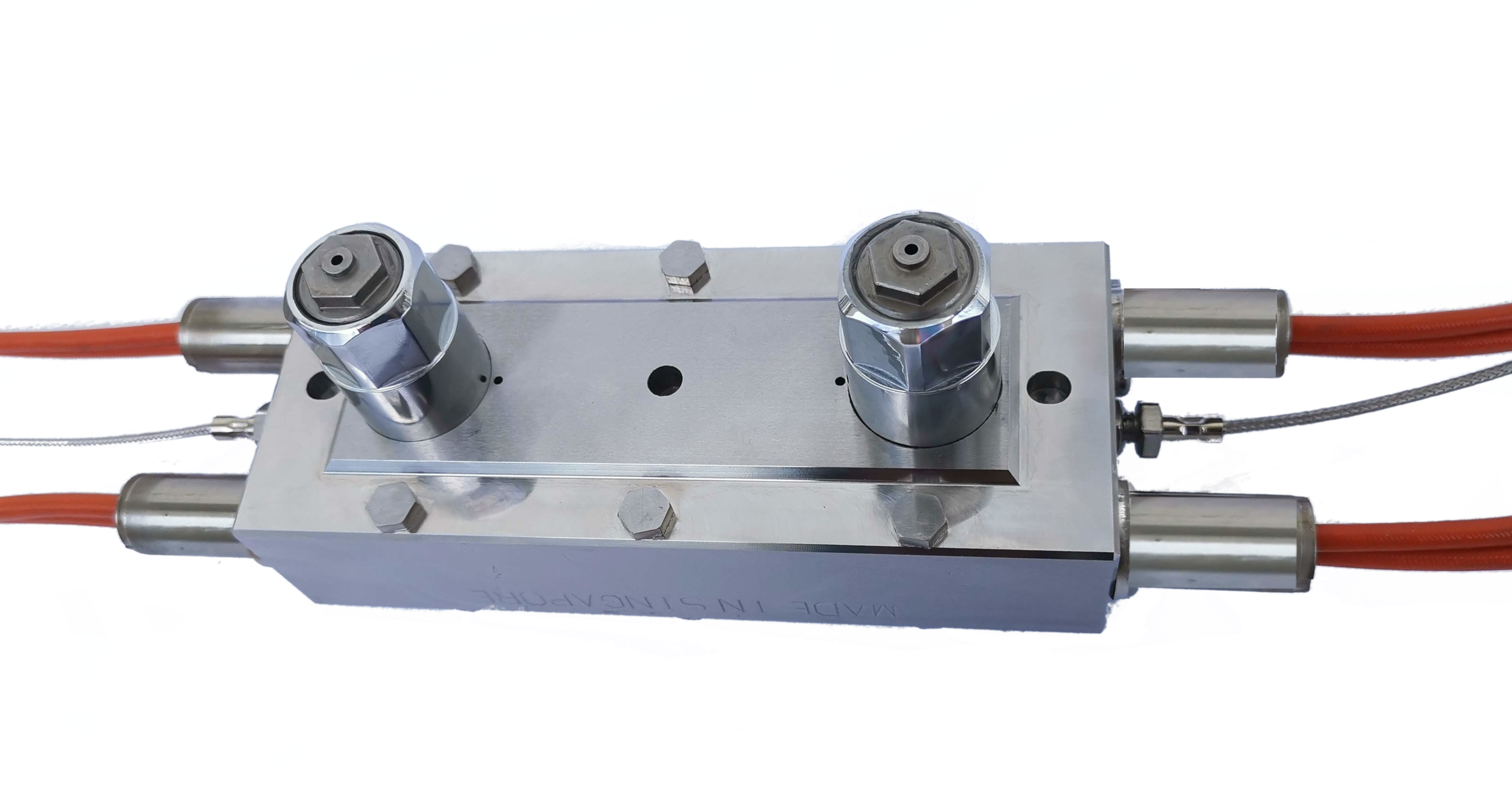

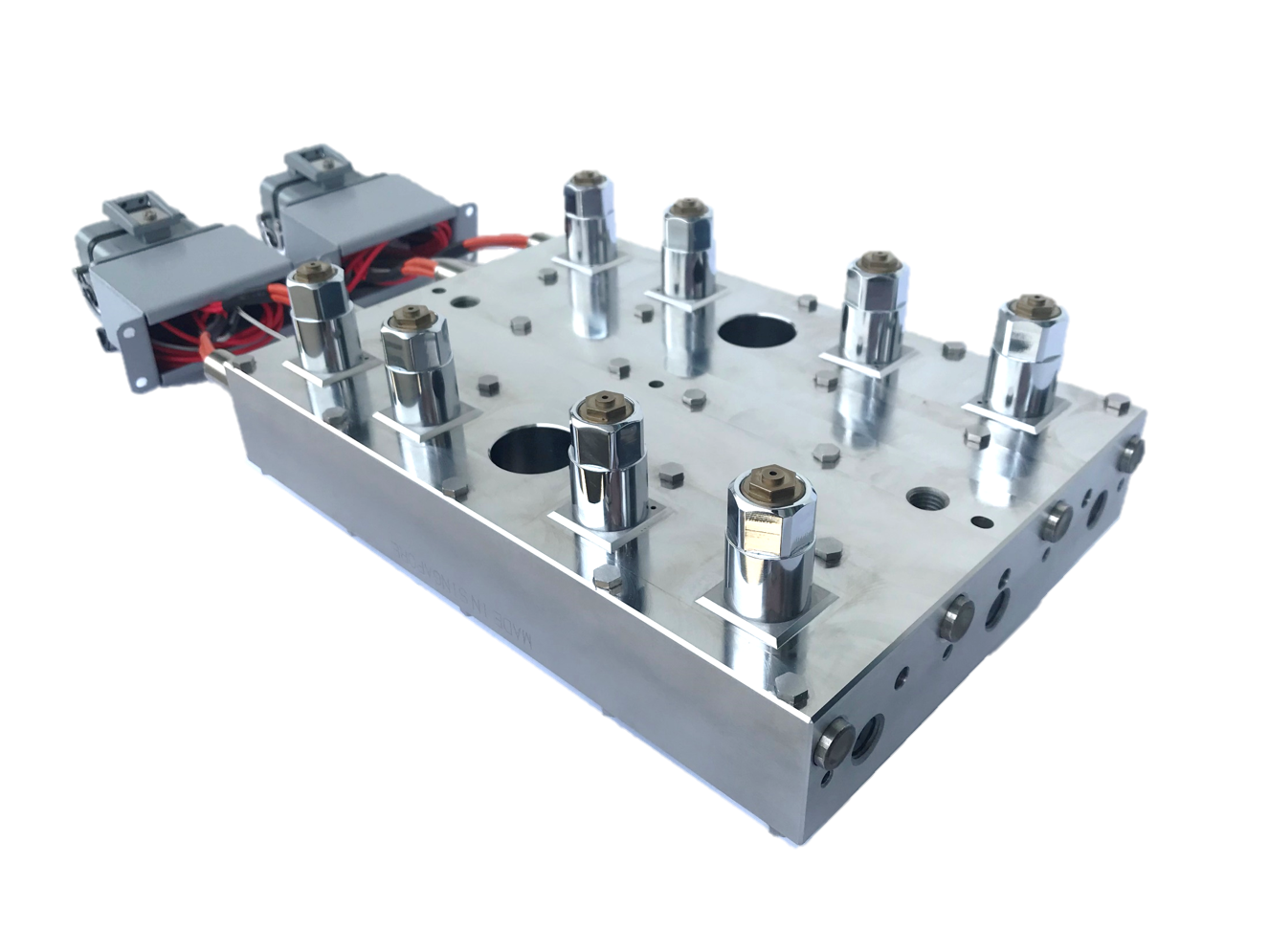

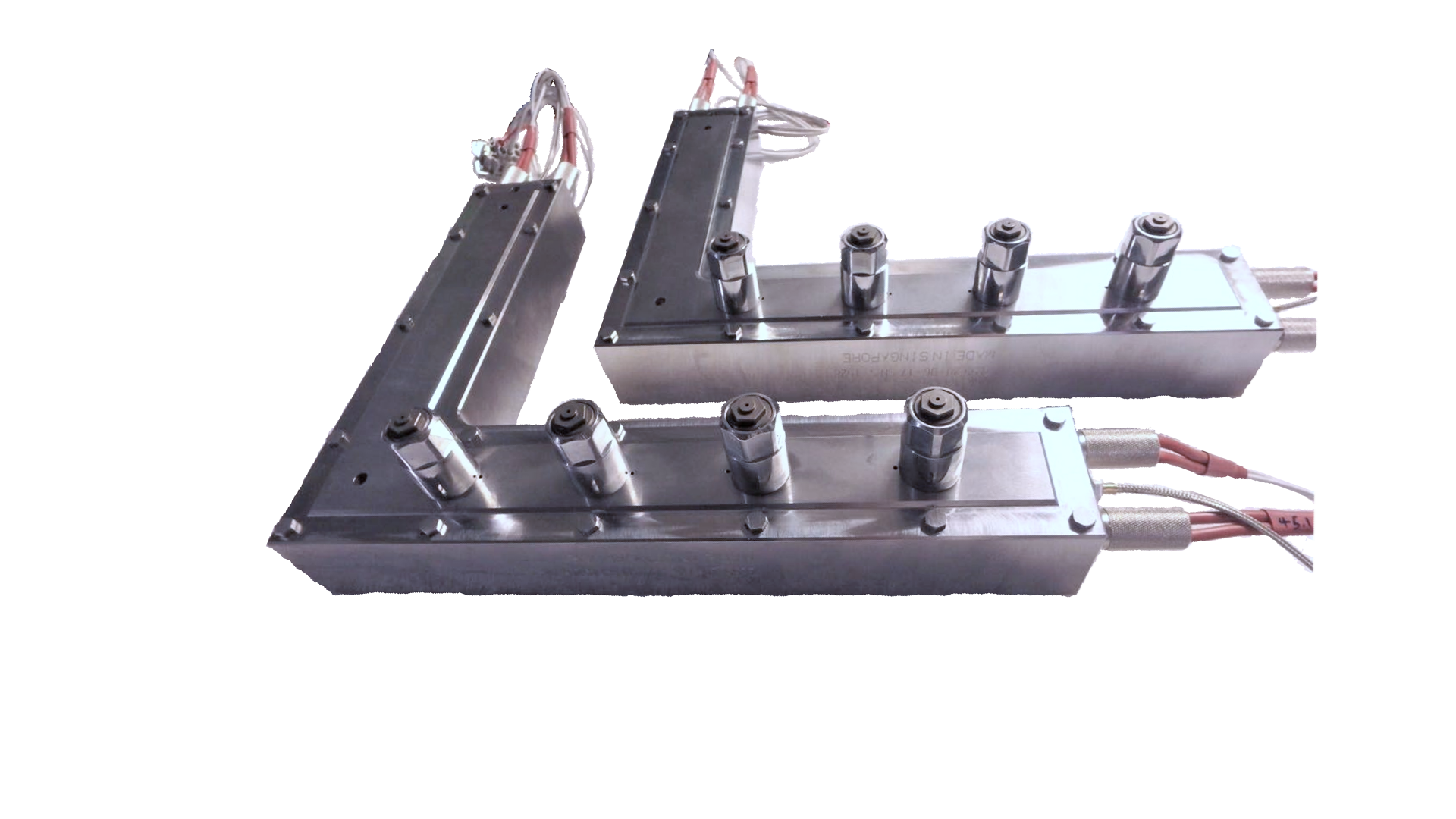

We offer various types of mini runner system manifolds, and can customise irregular manifold types as well. We also design manifolds to run on 2 colors, or to work with 2 materials.

Existing hot runner devices:

- Designed for molten resin to be led directly into the mold cavities to solidify.

- The molded product is solidified and no resin remains in the runners.

MSK Mini Runner System:

- Creates a smaller loss of resin in the runners, and avoids the problems associated with the existing types of runner devices.

- This is achieved as the system deals with the natural phenomenon of cooling and heating at the zero contact point.

Even though the MSK Mini Runner System has a small insignificant loss of resin in the runners, it has eliminated and solved almost all problems that the existing cold /hot runner system suffers from. This has made it the more efficient system with a greater increase of profits for the injection molding process.

Our solutions cater to applications such as:

- Injection molding of all resins, engineering plastics resin, ultra-high temperature plastics resin, metallic powder compound resin, thermosetting resin, rubber forming and more.

- Even with resins such as Ryton and PPS, the Mini Runner System is able to withstand melting temperatures above 400°C and continue to perform optimally.

What the Mini Runner System does best:

- Greatly reduces the amount of resin required in the runners

- Less use of resin translates to less heat required

- Shorter cooling time equates to shorter cycle time

How it will reduce your costs:

- Easy installation into mold as compared to the semi-hot runner system.

- A straight forward design requiring simple and little maintenance.

- Only requires a single zone temperature controller for the whole system, with a guaranteed temperature difference within 4°C.

- Applicable to all kinds of plastic materials.

- Makes changing the type and color of materials easier.

- Suitable for fitting both small and high precision products into the mold as it is customizable.

- Reduces wastage of runners by 50-80%, and cycle time by 15%-30%.

- Lower investment with faster returns.

- Minimizes energy consumption.

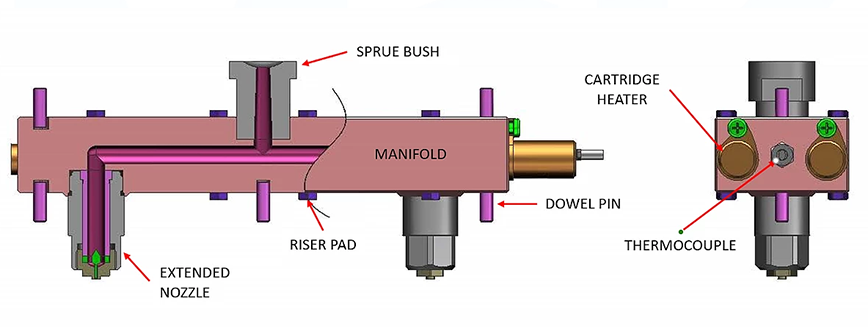

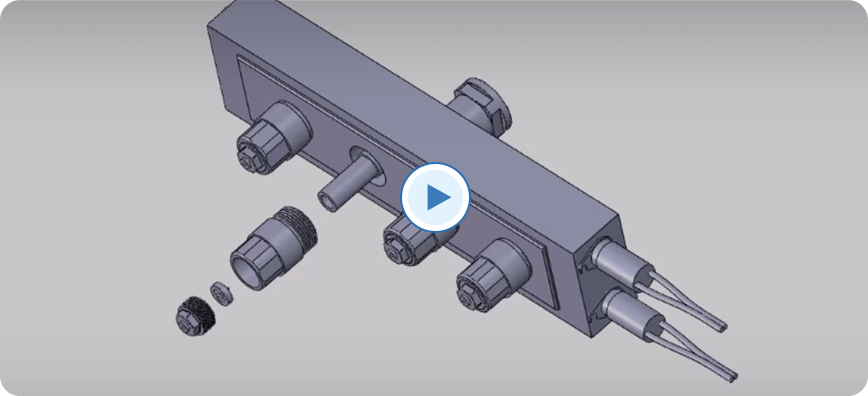

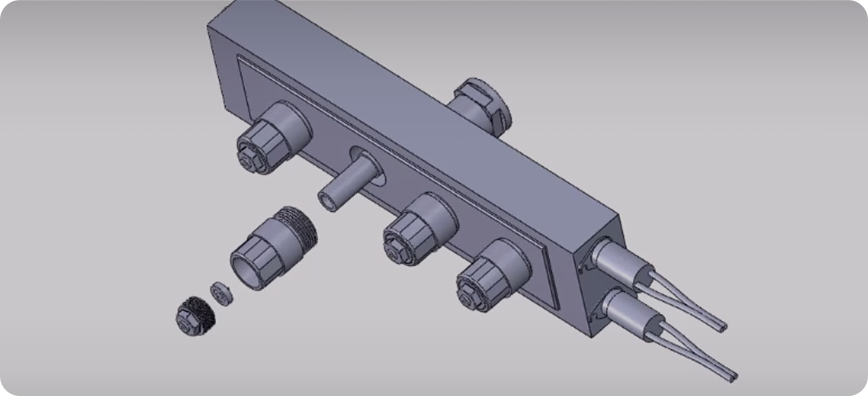

An example of the Mini Runner System’s construction: