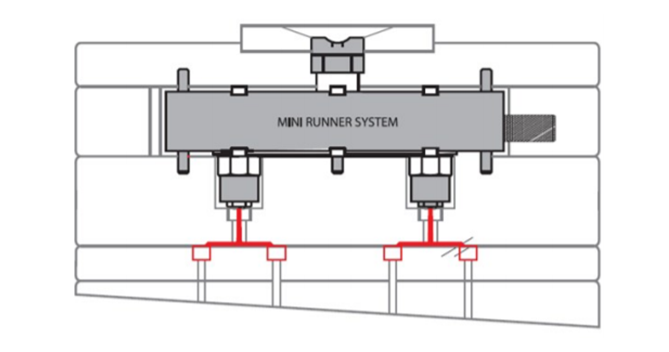

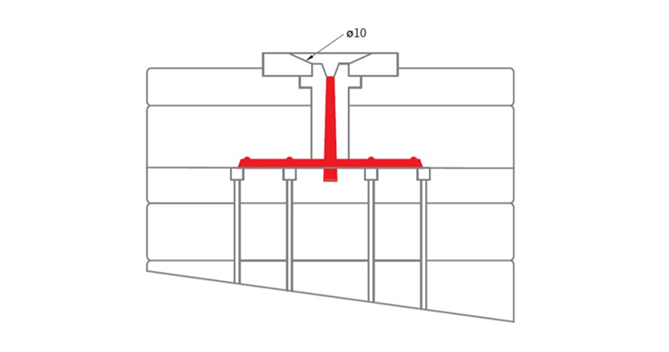

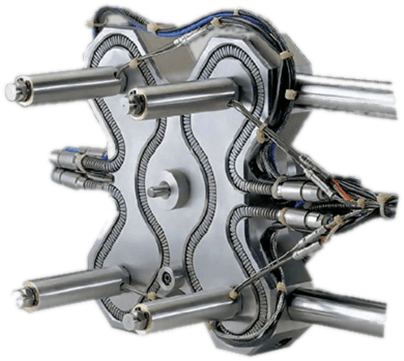

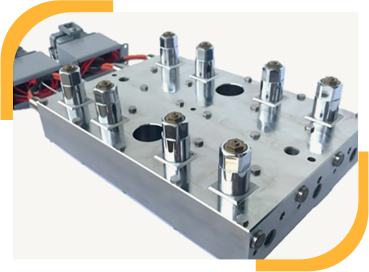

Mini Runner System Key Technologies

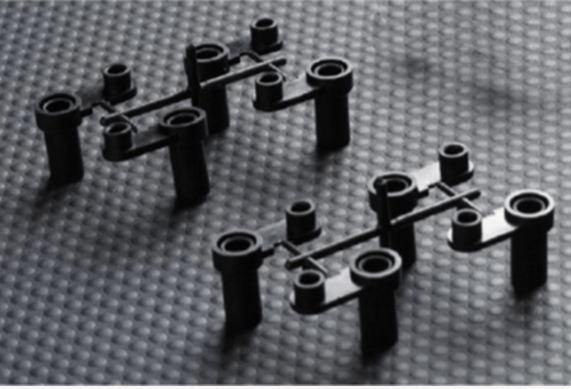

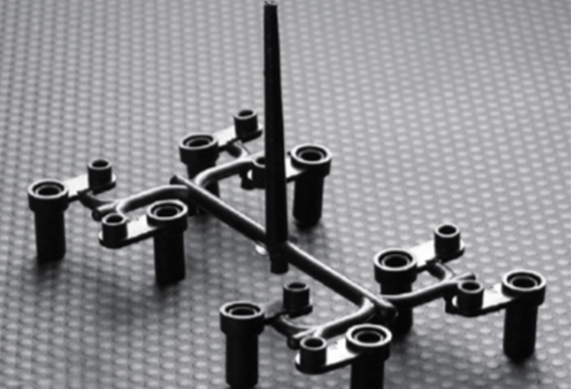

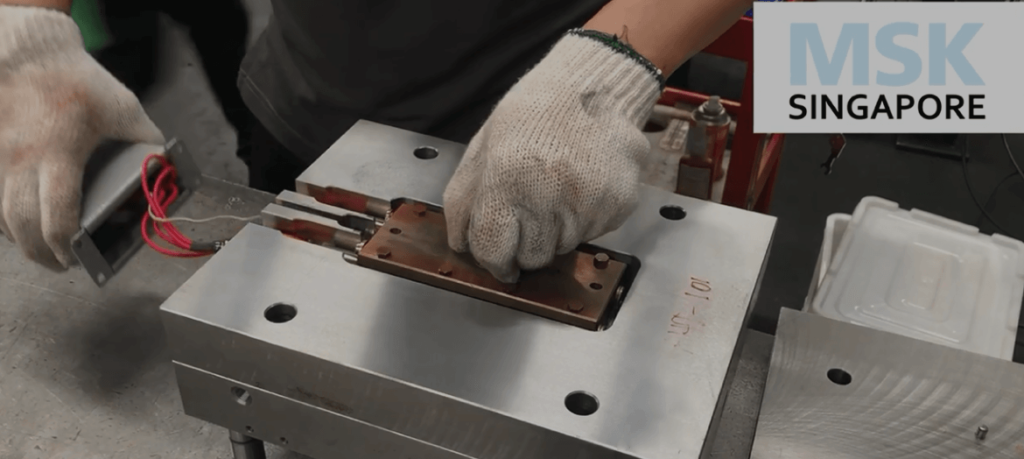

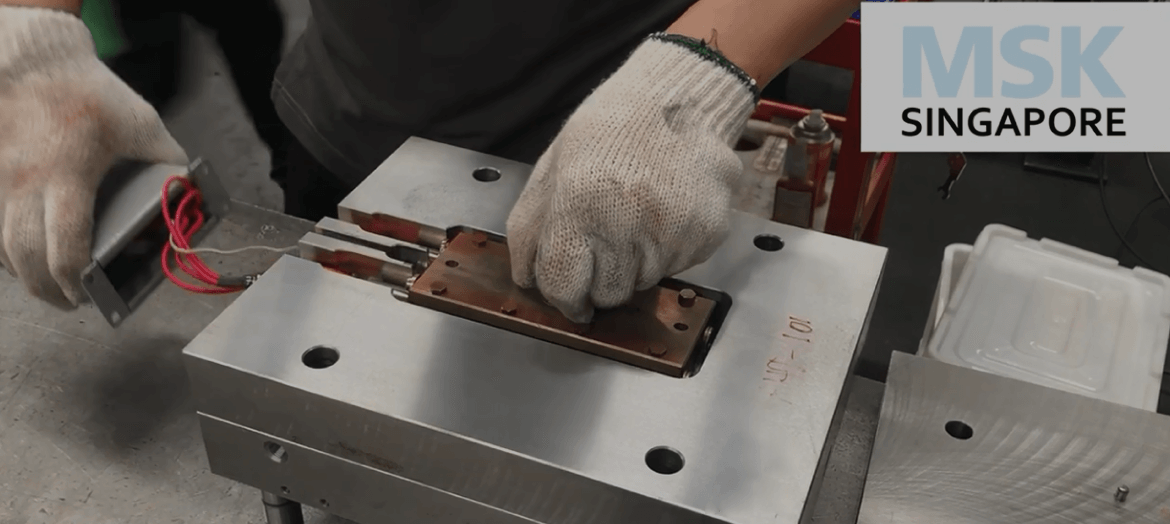

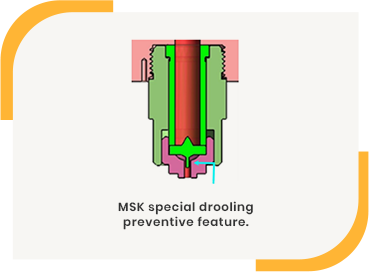

MSK Extended Nozzles Uniquely designed to prevent resin drooling and stringing. Suitable for all kinds of resin. Nozzle without heater control.

Resin drooling preventive mechanism:

Valve-less system that completely prevents leakage and stringing of resin.

Requires only 1 or 2 zone temperature controllers for the whole system, with a guaranteed temperature difference between nozzles within 4 °C. Less energy required. Saves wastage of runner by up to 80%.