Hot Sprue Bush

- The sprue portion of the runner wastes raw materials and obstructs resin flow, which in turn reduces molding quality, increases stress and causes excessive injection pressure.

- The sprue also takes longer to cool than the products do, causing the molding cycle to be longer than necessary.

- Eliminating the sprue halves the bulk of the runner, so production costs for transportation and storage are also halved.

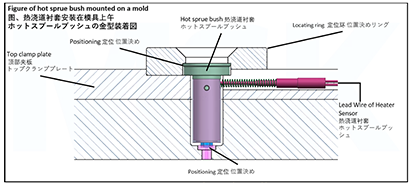

- The MSK Hot Sprue Bush replaces the sprue bush of a mold and is able to provide a smoother injection molding process.

Features:

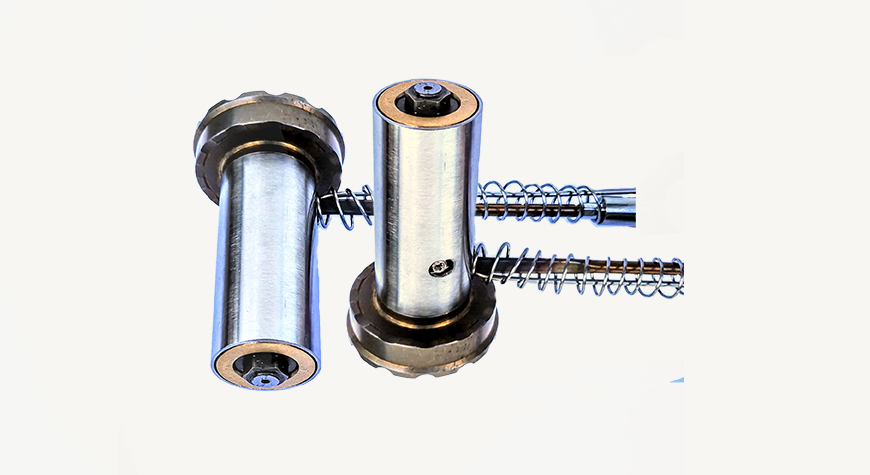

- When injection is complete, a valveless sealing system closes the gate, eliminating problems such as resin drooling and stringing. (Patent pending)

- We made the heating wire of the tubular heater last several times longer than that of an ordinary heater.

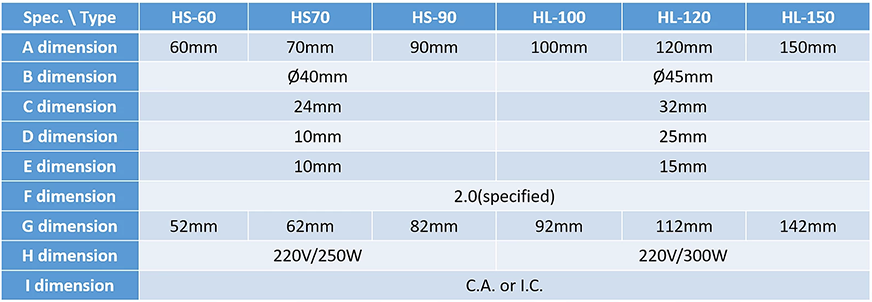

- The outer diameter of the hot sprue bush is only ø24 or ø32mm (standard) including the heater, so the mold stays rigid.

How it will reduce your costs:

- Product is tough enough to outlast several generations of molds.

How it will boost your efficiency and yield:

- Suits all resins

- Valveless sealing mechanism prevents stringing completely.

Construction of the Hot Sprue Bush:

- A high-precision abrasive-finished tubular heater is fitted on the cylindrical part of the sprue bush main body to form a hot sprue bush.

- The main body is made of highly heat- and pressure-resistant steel.