Case Study 3 - Runner Systems Comparison

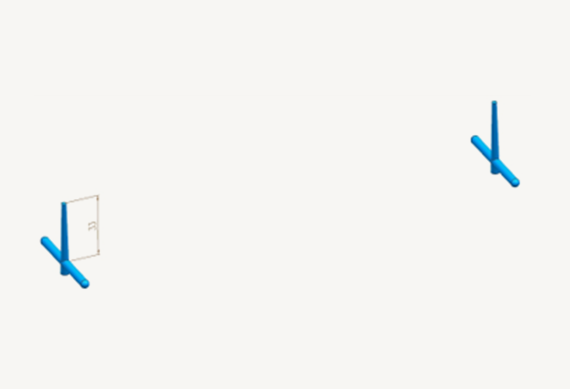

Before

( Cold runner)

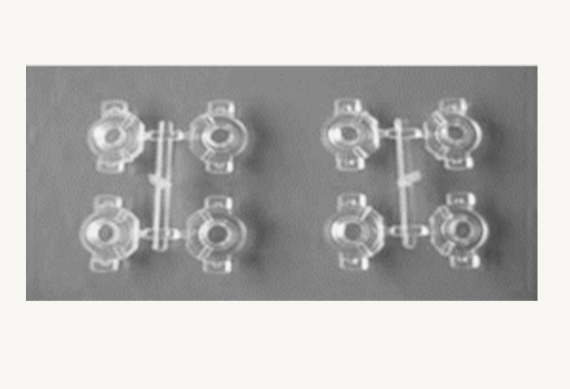

| No. of cavity | 32 |

| Material used | POM |

| Material cost (Est.) | US$ 1.50/kg |

| Qty/Month/Mould | 3000K pcs |

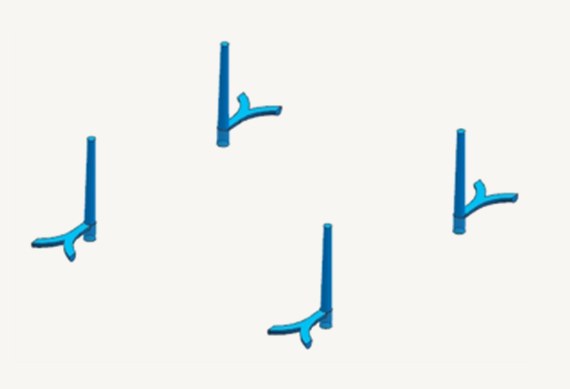

After

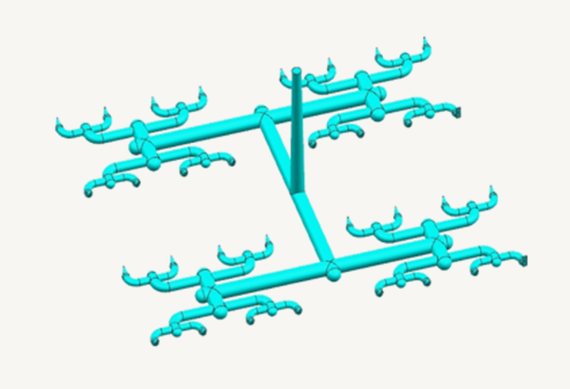

( Mini runner)

Product application: Consumer Products

| Runner System |

Runner weight |

Cycle time |

Productivity/day | |

| Before | Cold runner | 0,862 g/pc | 2,5 sec/pc | 92,503 pcs |

| After | Mini runner | 0,15 g/pc | 1,88 sec/pc | 148,859 pcs |

|

Approx.saving (cost of material @ US$ 3.00/kg& molding machine @ US$ 20/hr) |

0,458 g/pc (82%) | 0.343 sec/pc (38%) | 56,356 pcs (61%) | |

| US$ 0.000687 /pc | US$ 0.001905 /pc | |||

| Total saving (Material + Machine) | US$ 0.002592 /pc | |||

| MSK mini runner system cost | US$ 7,800 | |||

| Estimated ROI

ROI =

|

1.0 months | |||

| Approx.saving (Total saving x Qty/mth x 12) |

Year 1 – US$ 85,536 Year 2 – US$ 93,312

|

|||